#PIEZO TRANSDUCER SERIES#

When n number of transducers are stacked up in series one above the other, and electrically connected in parallel, the magnitude of charge can be calculated using the following equation: These devices use piezo transducers to generate vibrations and sound waves, which are precisely controlled to achieve optimal performance. In this impact the generated charges are specifically equivalent to the exerted force, but not depending on the piezo dimensions. Piezo transducers are essential components in many devices, including musical instruments, medical equipment, automotive systems, and ultrasonic cleaners. F x represents the force applied in the x-direction, while n represents the number of piezo elements stacked up one above the other. Where d xx denotes the piezoelectric coefficient for a charge across the x-direction, produced by the stress or the force applied across the same direction. The generated charge can be calculated using the following formula:

#PIEZO TRANSDUCER PROFESSIONAL#

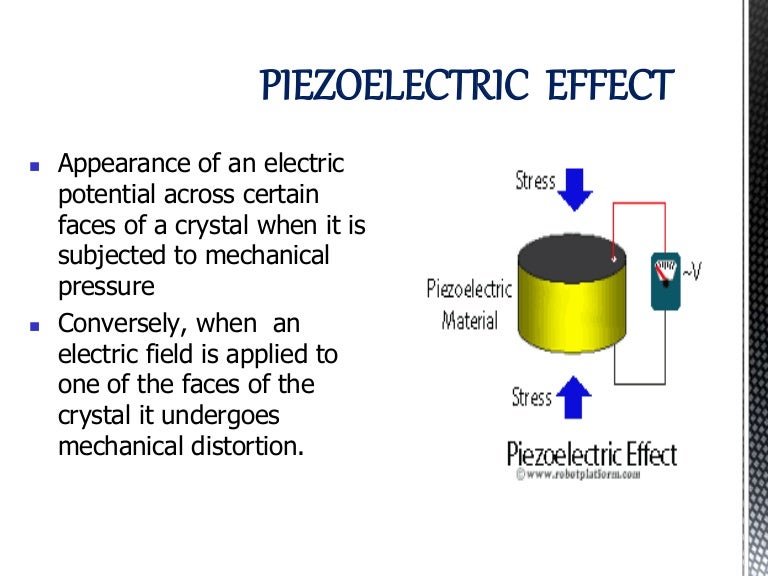

is one of the most professional and leading companies in the field of. Changzhou Cre-sound Electronics Co., Ltd. The only way to increase the charge output from a piezoelectric element is to configure many of these device mechanically in series or piled up one above the other, but electrically connected in parallel. Piezo Transducer 6 followers on LinkedIn. However this is not dependent on the piezoelectric dimensions. In this impact the magnitude of charge transferred is specifically equivalent to the force applied. Where a is the dimension across the neutral axis, b lies on the line which generates the charge, and d is relevant piezolectric coefficient. If we take a, b, d as the dimensions we get: The magnitude or the level of charge (Cz) produced depnds on the geometrical specifications of the piezo electric material. In this impact pressure is cuts along a neutral axis (y) moving charges along the (x) direction, perpendicular to the line of force. The application of this mechanical force on the piezo material could be in the following 3 basic forms: Technical Specs - How Piezo OperatesĪs we know that a piezoelectric transducer converts a mechanical force into equivalent electrical pulses across its body terminals.

The whole sticking (installation) procedure has been explained in this simple buzzer circuit article. The raised portion should be just 2 mm wide, barely supporting the circumference edge of the piezo. The plastic housing should be such that the piezo is stuck with a adhesive over a raise platform just a couple of mm above the base of the housing which consists of the above explained hole. The size of the hole matters and should not be more than 8mm in diameter or less than 6mm in diameter. However this sound can be very insignificant and low in volume unless the piezo is fixed over a special plastic housing with a center hole.

#PIEZO TRANSDUCER DRIVER#

The external frequency from a piezo driver is applied across the metal base and the inner piezo material, the piezo then starts vibrating at the applied frequency level, generating a high pitched sound. The above three contact piezo may also be used in two wire transducer application where the third central feedback contact is not used.

0 kommentar(er)

0 kommentar(er)